Un mouton produit beaucoup de déchets par an. Le fumier de mouton est une bonne matière pour la fabrication d’engrais organiques. Toutefois, il s’agit d’un déchet si vous ne vous en débarrassez pas. Grâce à la machine à fumier de mouton, vous pouvez transformer les déchets en engrais organiques précieux. Que votre ferme bovine soit de petite ou de grande taille, notre société vous propose une machine de traitement de fumier de mouton appropriée. En tant que fabricant expérimenté d’équipements de fertilisation, nous produisons des machines de production de fumier de mouton de haute qualité pour vous permettre de produire du fumier de mouton de haute qualité.

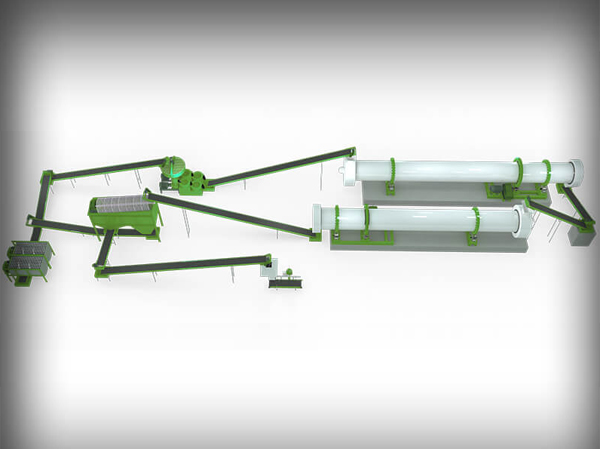

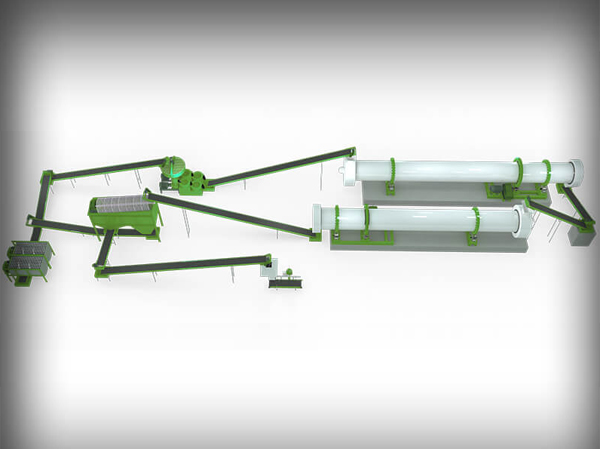

Ligne de production automatique d’engrais à base de fumier de mouton

capacité de traitement:1-100T/h

Champ d’application:transformation des excréments de volaille en engrais

L’engrais bio-organique à base de fumier de mouton est un engrais bio-organique mélangé à du fumier de mouton et à d’autres matières organiques, puis traité par fermentation, compostage, prétraitement et enfin granulé. Le fumier de mouton contient plus de matières organiques que les autres types de fumier, le fumier est plus fin et l’engrais est de meilleure qualité. La valeur calorique du fumier de mouton se situe entre celle du fumier de cheval et celle du fumier de bovin. Le fumier de mouton est donc une sorte d’engrais chaud qui convient aux sols sablonneux et aux sols argileux.

Il est recommandé aux petites usines nouvellement construites de produire annuellement 10000 tonnes (1,5 tonne/heure), 20000 tonnes (3 tonnes/heure) et 30000 tonnes (4,5 tonnes/heure), tandis que les usines de taille moyenne peuvent produire annuellement 50000 à 100000 tonnes et les grandes usines peuvent produire annuellement 100000 à 300000 tonnes. L’échelle d’investissement et la conception du plan de production doivent être formulées en fonction des conditions suivantes : caractéristiques des ressources en matières premières, conditions pédologiques locales, structure de plantation locale et variétés de cultures principales, conditions du site de l’usine, degré d’automatisation de la production, etc.

L’équipement de production d’engrais organiques à base de fumier de mouton est un dispositif qui utilise le fumier de mouton comme matière première principale, ajoute une certaine quantité d’engrais azoté, d’engrais phosphoré, d’engrais potassique, de sulfate de magnésium, de sulfate ferreux et d’autres substances, fait fermenter du son de riz, de la levure, de la farine de soja et du sucre pendant un certain temps en tant que bactéries biologiques et, sous l’action de l’acide sulfurique, mélange et fait fermenter pour produire des engrais biologiques.

Équipement de production et processus de fabrication de l’engrais organique à base de fumier de mouton

Granulation à disque, granulation à tambour, granulation par extrusion -5. Machine de séchage pour les particules d’engrais organiques -6. Machine de refroidissement pour les particules d’engrais organiques -7. Machine de criblage pour les particules d’engrais organiques qualifiées -8. Machine d’enrobage pour des particules d’enrobage plus lisses -9. Balance d’emballage pour le remplissage automatique des particules d’engrais organique -10. Scellement

Ligne de production d’engrais organiques à base de fumier de mouton

Les déchets de bétail et de volaille recyclés sont directement transférés dans la zone de fermentation. Après une fermentation, un empilage de vieillissement secondaire, l’odeur du fumier de bétail et de volaille est éliminée. À ce stade, des souches de fermentation peuvent être ajoutées pour décomposer les fibres grossières, de sorte que la taille des particules après le broyage corresponde aux exigences de la production de granulés.

deux Les matériaux de fermentation qui ont terminé le processus d’empilage de vieillissement secondaire sont broyés et introduits dans le système de mélange. Avant le mélange et le malaxage, N, P, K et d’autres oligo-éléments sont ajoutés au système de malaxage selon la formule pour commencer le mélange.

Troisièmement. Le matériau mélangé est transporté dans le système de granulation, les particules entrent dans le système de refroidissement après le sécheur, le matériau est criblé à température ambiante, les particules qui répondent aux exigences entrent dans la machine d’enrobage et commencent à être emballées, et les particules qui ne répondent pas aux exigences sont broyées par le concasseur et renvoyées dans le système de granulation pour continuer la granulation.Quatre. Emballage automatique des produits finis.

Configuration de la ligne de production d’engrais à base de fumier de mouton – partie fermentation des matières premières et broyage

| NAME | Specifications | Quantity | Remark |

|---|---|---|---|

| Trough tipping machine | ZCFD-3000 | 1 | Includes a shift car (tank changing car), shift motor, electrical control cabinet, remote control handle, and cable drum for customer selection (The track needs to be purchased by the customer) According to customer requirements, our company has flipping equipment with a width of 2-20 meters and a flipping depth of 0.8-3 meters. |

| Forklift feeder | ZCW-2030 | 1 | Includes uniform discharge device, anti smashing net device, mixing anti blocking device, and vibration anti blocking device. The capacity of the silo is about 5m3, greatly reducing the workload of the forklift operator, and the forklift driver can also operate the stacker. The function of this device is to uniformly transport raw materials to the crusher. |

| Drum screen | ZGS-1240 | 1 | The screen mesh is made of stainless steel material to prevent corrosion. According to customer requirements, a striking anti sticking net device can be added. |

| Vertical composite mill | ZLFF-600 | 1 | The crusher adopts a chain blade composite structure, which can crush materials with a moisture content of less than 40% to a granulation state. The chain is made of high manganese alloy, and the blades are made of spring steel material, which has the advantage of durability and wear resistance. The rotor is dynamically balanced and can operate stably without the need for a foundation. |

| Three warehouse dynamic batching | ZZP-1515 | 4 | The size of this silo is customized according to the customer’s ratio. The part in contact with the material can be made of 304 stainless steel material. The computer quantitative weighing system adopts imported sensors and instruments, with high measurement accuracy, ingredient accuracy of ≤± 0.5%, packaging accuracy of ≤± 0.2%, and reliable operation. |

Sheep manure feed production line configuration — granulation part

| NAME | Specifications | Quantity | Remark |

|---|---|---|---|

| Single-shaft mixer | ZSJ-0830 | 1 | The mixing blade adopts a double spiral structure, which ensures uniform mixing and high efficiency. The mixing blades are made of high-strength and wear-resistant materials, which have a longer service life. The minimum gap between the rotor and the shell can be adjusted to near zero, effectively reducing the amount of material residue. Mixing capacity: 5-8t/h Body thickness: 6mm Dimensions: 3800 * 1320 * 770mm Reducer model: JZQ350-31.5 Mixing speed: 34r/min |

| Stir tooth granulator | ZZGZ-600 | 1 | The interior of the barrel is lined with rubber sheets, which automatically remove scars. Anti corrosion insulation. The support wheel frame and transmission gear ring roller belt of the granulator are all made of cast steel material. Barrel thickness: 14mm, barrel inner diameter: 1800mm, barrel length: 6000mm. Material Q345. Adopting a one-time forming spiral tube. Production capacity: 7-9t/h Rotation speed: 11.5r/min |

| Rotary dryer | ZHG-1010 | 1 | The dryer cylinder is a 14mm thick integrated spiral tube, which has the advantages of high concentricity, strong rigidity, and smooth operation. The thickness of the lifting plate is 8mm. The gear ring, rolling belt roller, and bracket are all cast steel parts. The induced draft fan is self-made by the company and has undergone static and dynamic balance calibration, resulting in stable and high-intensity operation. Adopting a co current drying method, the material and heat source airflow enter the drying equipment from the same side, resulting in a low outlet temperature and high thermal efficiency of the dryer. Choose reasonable operating parameters to balance the « coal, material, and air », thereby greatly improving the thermal efficiency of the dryer and reducing drying energy consumption by more than 30-50%. |

| Rotary cooling machine | ZLQ-0880 | 1 | The cooling machine cylinder is a 14mm thick integrated spiral tube, which has the advantages of high concentricity, strong rigidity, and smooth operation. The thickness of the lifting plate is 6mm. The gear ring, rolling belt roller, and bracket are all cast steel parts. The induced draft fan is self-made by the company and has undergone static and dynamic balance calibration, resulting in stable and high-intensity operation. Choose reasonable operating parameters to balance the « material and air », thereby greatly improving the cooling efficiency of the cooling machine and reducing cooling energy consumption by more than 20-50%. |

| Drum screen | ZGS-1240 | 1 | The screen mesh is made of stainless steel material to prevent corrosion. According to customer requirements, a striking anti sticking net device can be added. The function of this screening machine is to screen the crushed raw materials, the finished products enter the granulation process, and the waste products are returned for re crushing. The finished product is also a powdered organic fertilizer |

Sheep fertilizer feed production line configuration — supporting equipment

| NAME | Specifications | Quantity | Remark |

|---|---|---|---|

| There is a bucket pellet packaging machine | ZKB | 1 | The parts in contact with the material are made of 304 stainless steel material. Specially designed feeding and bucket metering are carried out simultaneously with bagging and unloading. Save one-third of homework time, fast packaging speed, and high packaging accuracy. Imported sensors and pneumatic actuators are used, which are reliable in operation and easy to maintain. Measurement accuracy is plus or minus two thousandths. Wide quantitative range, high accuracy, combined with a conveyor sewing machine that can be raised and lowered on the table, making it versatile and efficient. |

| Finished product warehouse | ZLC-1200 | 1 | The finished organic fertilizer warehouse is widely used in various fertilizer production lines to undertake the transfer equipment that is quickly transported to the belt conveyor and transported by the belt conveyor to the next deep processing link. This finished product warehouse, equipment material quality, durable. |

| Chain return mill | ZLTF-500 | 1 | The outer wall of the crusher is made of 8mm thick manganese steel plate. The crusher chain adopts a high-strength alloy chain. The crushed material is uniform, not easy to stick to the wall, and easy to clean. The inner wall can be made of rubber or stainless steel (depending on customer needs) to achieve a smooth surface and easy cleaning. Quick opening maintenance doors are installed on both sides of the body, and the body and transmission device are mounted on a steel base. A shock absorber is installed at the bottom of the base and connected to the foundation. |

| Cyclone dust collector | ZXC-900 | 2 | The cyclone dust collector has a simple structure, is easy to manufacture, install, and maintain, and has low equipment investment and operating costs. The cyclone dust collector is composed of an intake pipe, an exhaust pipe, a cylindrical body, a conical body, and an ash hopper. Each component of the cyclone dust collector has a certain size ratio, and the diameter of the dust collector, inlet size, and exhaust pipe diameter are all accurately calculated by engineers. Ensure the best dust removal effect is achieved. |

| Induced draft fan | ZYF-6C | 15 | The induced draft fan is self-made by the company and has undergone static and dynamic balance calibration, resulting in stable and high-intensity operation. The induced draft fan and connecting pipeline are matched with the dryer. The impeller consists of 10 aft inclined blade types, a curved front plate, and a flat rear plate. Made of copper plate or cast aluminum alloy, and calibrated for dynamic and static balance, it has good air performance, high efficiency, and smooth operation. The air inlet is made as a whole and installed on the side of the fan. The cross-section parallel to the axial direction is curved, which allows gas to enter the impeller smoothly with minimal loss. |

Sheep manure bio-organic fertilizer production line refers to mixing some organic matter such as straw, straw, wood chips or living kitchen waste with sheep manure, composting fermentation, drying and pretreatment, and then entering the processing workshop, after grinding, mixing, granulation, cooling, packaging section processing, to make bio-organic fertilizer